SC Speedcut aluminium end mill, long, optional, twin blade, variable helix DIN 6527L

End mill SC Alu DIN6527L Z2 3xD/2xD 43-45° HB

ENDMIL-SP-DIN6527L-ALU-SC-WF-D12

Art.-no. 5443300927

EAN 4055375918616

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 7135 |

Material to be processed | Aluminium, Copper, Brass, Plastic |

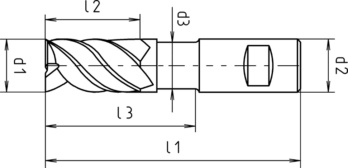

Diameter (d1) | 12 mm |

Shank diameter (d2) | 12 mm |

Clearance diameter (d3) | 11.5 mm |

Standards | DIN 6527 |

Construction length | Long |

Shank style | Cylindrical DIN 6535-HB |

Cutting material | SC |

Surface | Plain |

Coolant supply | External |

Twist angle | 43-45° |

Length (l1) | 83 mm |

Cutting edge length (l2) | 26 mm |

Clearance length (l3) | 38 mm |

Number of cutting edges (Z) | 2 PCS |

Corner chamfer | 0.15 mm |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Aluminium, Copper, Brass, Plastics |

| Key | ||

| T = dry | ae = 0.5xd1 | |

| E = emulsion | ||

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for roughing groove | ||||||||

| For dia. 3 to dia. 8 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 500 | 0,070 | 0,085 | 0,095 | 0,110 | 0,140 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 475 | 0,070 | 0,085 | 0,095 | 0,110 | 0,140 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 250 | 0,064 | 0,074 | 0,085 | 0,092 | 0,140 |

| Copper, low-alloy | < 350 N/mm² | E | 135 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 |

| Brass, short-chipping | < 600 N/mm² | E | 250 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 |

| Brass, long-chipping | < 600 N/mm² | E | 175 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 |

| Bronze, short-chipping | < 600 N/mm² | E | 175 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 |

| 650-850 N/mm² | E | 135 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 | |

| Bronze, long-chipping | < 850 N/mm² | E | 135 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 |

| 850-1200 N/mm² | E | 120 | 0,044 | 0,056 | 0,068 | 0,082 | 0,120 | |

| Plastics | Thermoplastic | E/T | 250 | 0,022 | 0,030 | 0,040 | 0,050 | 0,064 |

| Duroplastic | E/T | 250 | 0,022 | 0,030 | 0,040 | 0,050 | 0,064 | |

| Cutting values for roughing contour | |||||||

| For dia. 10 to dia. 20 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 10 | Dia. 12 | Dia. 16 | Dia. 20 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 580 | 0,192 | 0,216 | 0,264 | 0,336 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 530 | 0,192 | 0,216 | 0,264 | 0,336 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 290 | 0,240 | 0,288 | 0,360 | 0,456 |

| Copper, low-alloy | < 350 N/mm² | E | 160 | 0,180 | 0,216 | 0,264 | 0,336 |

| Brass, short-chipping | < 600 N/mm² | E | 290 | 0,180 | 0,216 | 0,264 | 0,336 |

| Brass, long-chipping | < 600 N/mm² | E | 205 | 0,180 | 0,216 | 0,264 | 0,336 |

| Bronze, short-chipping | < 600 N/mm² | E | 205 | 0,180 | 0,216 | 0,264 | 0,336 |

| 650-850 N/mm² | E | 170 | 0,180 | 0,216 | 0,264 | 0,336 | |

| Bronze, long-chipping | < 850 N/mm² | E | 170 | 0,180 | 0,216 | 0,264 | 0,336 |

| 850-1200 N/mm² | E | 145 | 0,180 | 0,216 | 0,264 | 0,336 | |

| Plastics | Thermoplastic | E/T | 250 | 0,080 | 0,100 | 0,120 | 0,164 |

| Duroplastic | E/T | 250 | 0,080 | 0,100 | 0,120 | 0,164 | |

| Cutting values for roughing contour | ||||||||

| For dia. 3 to dia. 8 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 580 | 0,105 | 0,170 | 0,250 | 0,132 | 0,168 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 530 | 0,105 | 0,170 | 0,250 | 0,132 | 0,168 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 290 | 0,096 | 0,099 | 0,105 | 0,110 | 0,168 |

| Copper, low-alloy | < 350 N/mm² | E | 160 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 |

| Brass, short-chipping | < 600 N/mm² | E | 290 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 |

| Brass, long-chipping | < 600 N/mm² | E | 205 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 |

| Bronze, short-chipping | < 600 N/mm² | E | 205 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 |

| 650-850 N/mm² | E | 170 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 | |

| Bronze, long-chipping | < 850 N/mm² | E | 170 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 |

| 850-1200 N/mm² | E | 145 | 0,066 | 0,077 | 0,088 | 0,098 | 0,144 | |

| Plastics | Thermoplastic | E/T | 250 | 0,022 | 0,031 | 0,040 | 0,050 | 0,064 |

| Duroplastic | E/T | 250 | 0,022 | 0,031 | 0,040 | 0,050 | 0,064 | |

| Key | ||

| T = dry | ae = 1xd1 | |

| E = emulsion | ||

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for roughing groove | |||||||

| For dia. 10 to dia. 20 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 10 | Dia. 12 | Dia. 16 | Dia. 20 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 500 | 0,160 | 0,180 | 0,220 | 0,280 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 475 | 0,160 | 0,180 | 0,220 | 0,280 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 250 | 0,200 | 0,240 | 0,300 | 0,380 |

| Copper, low-alloy | < 350 N/mm² | E | 135 | 0,150 | 0,180 | 0,220 | 0,280 |

| Brass, short-chipping | < 600 N/mm² | E | 250 | 0,150 | 0,180 | 0,220 | 0,280 |

| Brass, long-chipping | < 600 N/mm² | E | 175 | 0,150 | 0,180 | 0,220 | 0,280 |

| Bronze, short-chipping | < 600 N/mm² | E | 175 | 0,150 | 0,180 | 0,220 | 0,280 |

| 650-850 N/mm² | E | 135 | 0,150 | 0,180 | 0,220 | 0,280 | |

| Bronze, long-chipping | < 850 N/mm² | E | 135 | 0,150 | 0,180 | 0,220 | 0,280 |

| 850-1200 N/mm² | E | 120 | 0,150 | 0,180 | 0,220 | 0,280 | |

| Plastics | Thermoplastic | E/T | 250 | 0,080 | 0,100 | 0,120 | 0,164 |

| Duroplastic | E/T | 250 | 0,080 | 0,100 | 0,120 | 0,164 | |