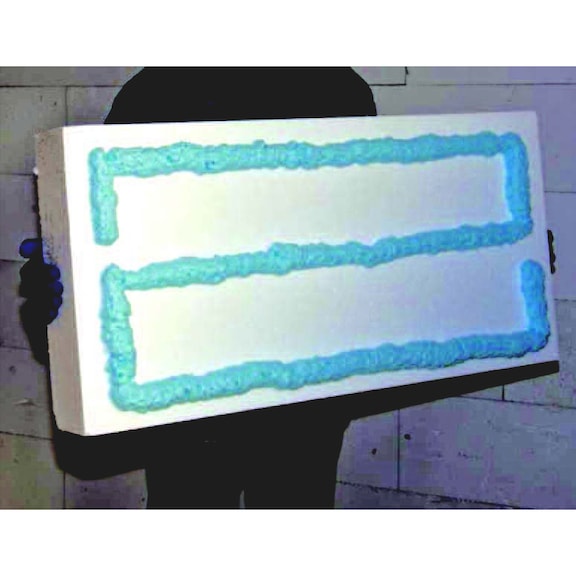

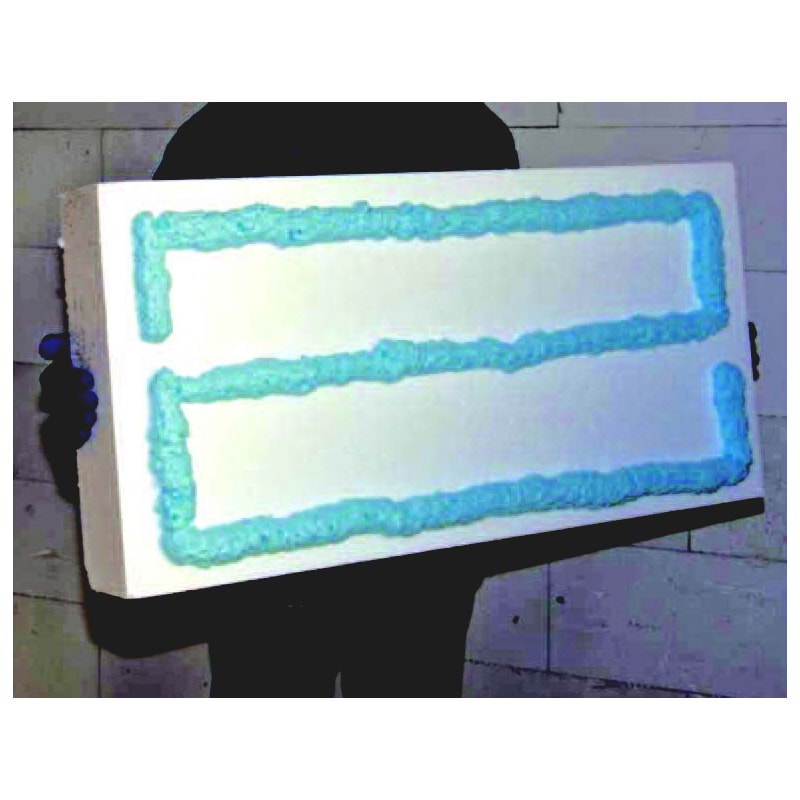

Styrofoam adhesive STYRO W101

Adhesive PU for insulation sheet

ADH-INSUSHT-BLUE-750ML

Register now and access more than 125,000 products

- No power tools, water or special equipment are required.

- Excellent thermal and acoustic insulation properties.

- Fast-setting, Styrofoam boards can be anchored just two hours after gluing.

- Waiting time for the next stages of construction works are significantly shortened (anchoring, application of mesh reinforced mortar, plastering).

Datasheets(X)

- Suitable for gluing Styrofoam and XPS panels to walls, foundations, building substructures, flat roofs for thermal insulation;

- Styrofoam coffers, lightweight decorative elements, decorative mouldings;

- windowsills, plasterboards;

- filling gaps in thermal building insulation panels.

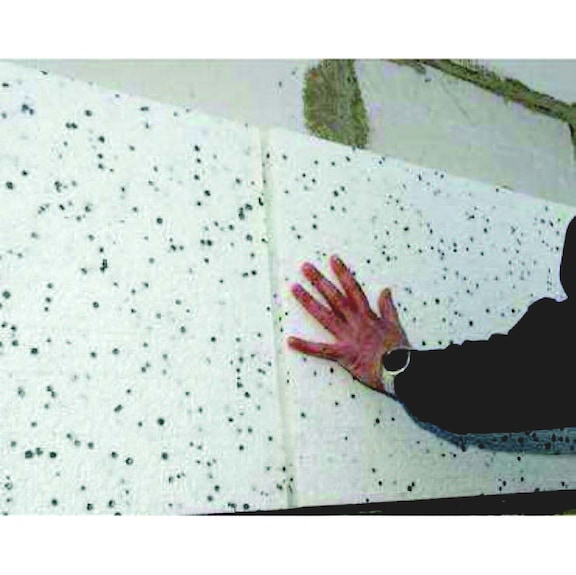

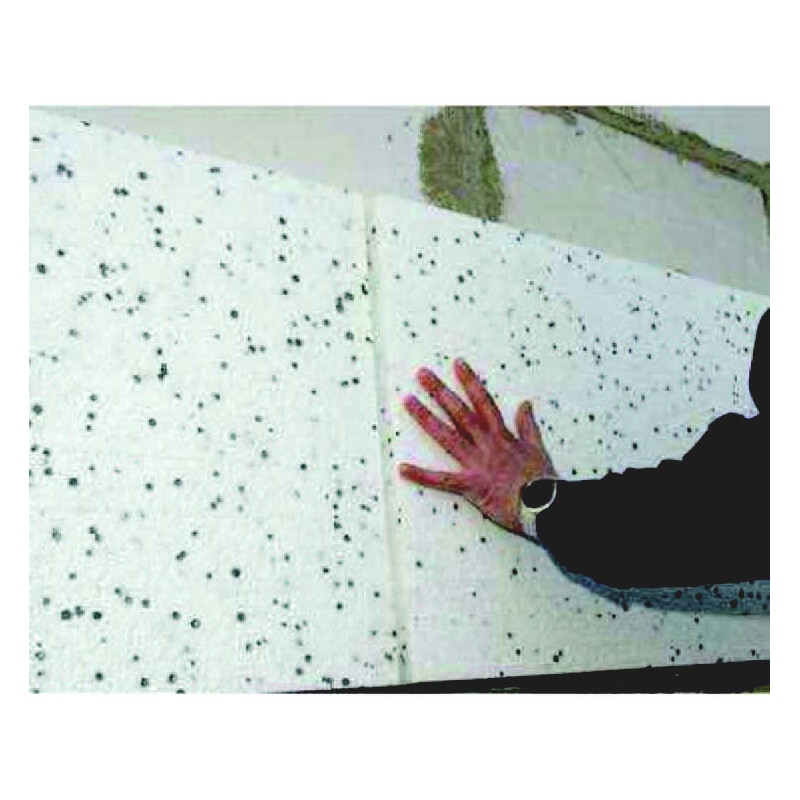

For foundations and roofs, apply the adhesive to the panels in vertical beads with a diameter of 2 cm, parallel to the short edge of the panel. The glued Styrofoam panels can be adjusted within approx. 15 minutes after gluing.

Chemical basis | Single component polyurethane |

Colour | Blue |

Tack-free after | 10 min |

Conditions for being tack-free | at 23°C and 50% humidity |

Curing time | 2 h |

Fully hardening/curing conditions | 23°C and 50% relative humidity |

Full resilience | 24 h |

Conditions for full resilience | at 23°C and 50% relative humidity |

Min. processing temperature | 5 °C |

Max. processing temperature | 30 °C |

Min. surface processing temperature | 5 °C |

Max. surface processing temperature | 30 °C |

Min. temperature resistance | -60 °C |

Max. temperature resistance | 100 °C |

Yield (volume) approx. | 750 ml |

Yield (area) | 10 m² |

Contents | 750 ml |

Weight of content | 980 g |

Building material class | B3 - Of high flammability |

Building material class conditions | in accordance with DIN 4102 |

Resistance against | Aging |

Min. compressive strength | 50 kPa |

Max. compressive strength | 60 kPa |

Max. tensile strength | 150 kPa |

Min. tensile strength | 100 kPa |

Compressive strength conditions | after 28 days, 23°C and 50% relative humidity |

Heat conductance λ | 0.036 W/(m*K) |

Heat conductance λ conditions | at 23°C |

Min./max. tensile strength | 100-150 kPa |

Conditions for tensile strength | in accordance with DIN EN 1607 |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | at 10°C to 30°C |